When and How to Replace an Air Compressor Belt (With Pro Tips)

Posted by Industrial Air Centers on 09/29/2025

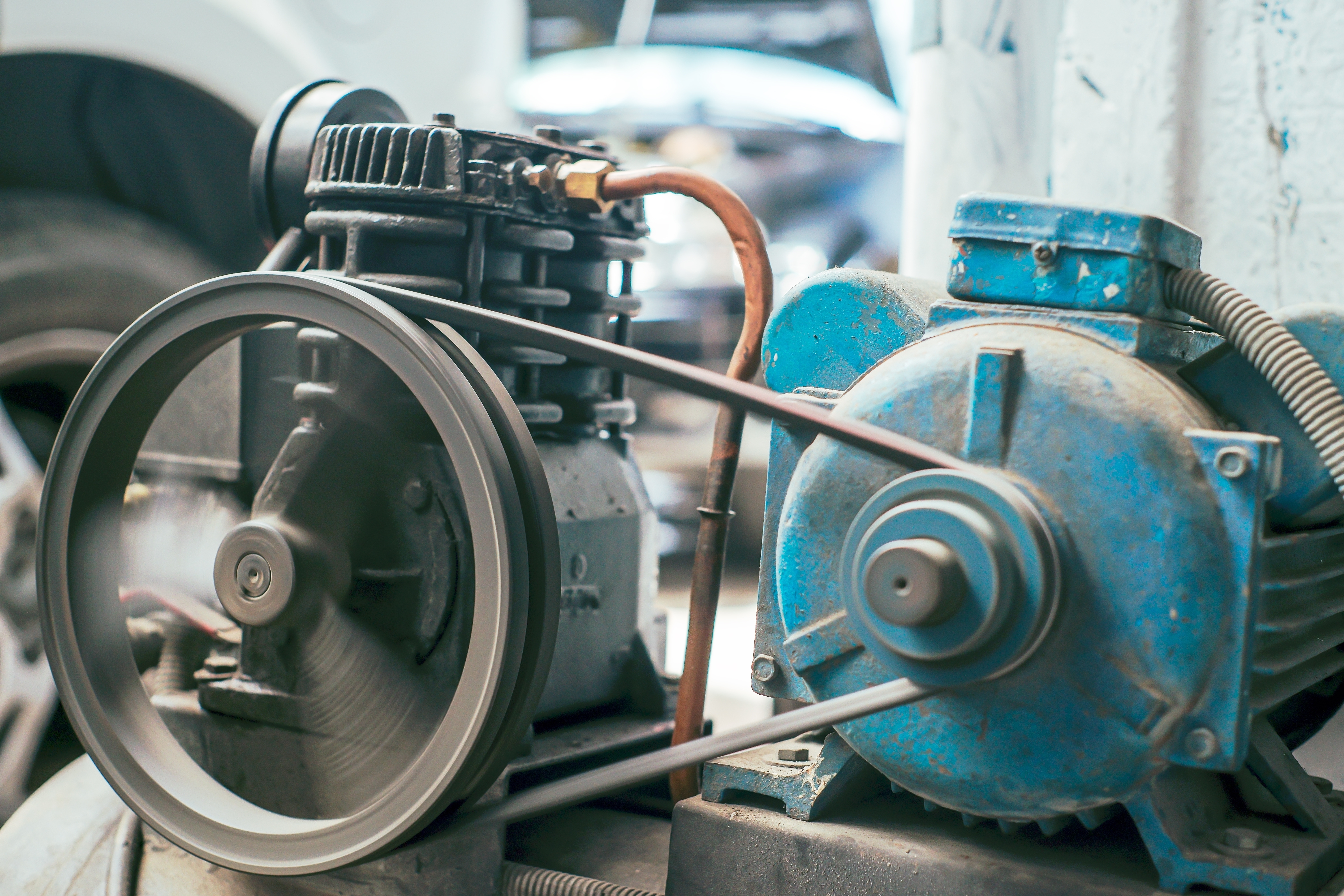

When an air compressor belt wears out, it’s more than an inconvenience, it can stop your entire operation until it’s replaced. In an industrial setting, that single strip of reinforced rubber is what transfers power from the motor sheave to the compressor pump/airend. No belt = no airflow = no production.

Timely replacement matters because a worn or slipping belt doesn’t just reduce output; it drives up heat, amps, and vibration that can snowball into bigger costs: glazed sheaves, premature bearing wear, nuisance trips, and unplanned downtime. Catching belt wear early (cracking, glazing, frayed cords, black dust, frequent re-tensioning) protects your compressor, your energy budget, and your schedule.

In this guide, we’ll walk through a clear, DIY-friendly process. This includes what to check, how to select the right belt, and how to replace it safely with proper alignment and tension, plus the pro tips that reduce callbacks (like re-tension after run-in and always reinstalling guards). We’ll also flag exactly when to call a professional (multi-belt sets that won’t track, recurring vibration, sheave wear, electrical/VFD issues) so you’re not taking on unnecessary risk.

Our Goal: Help maintenance teams act fast and confidently, while making it simple for plant managers to keep lines running and costs controlled.

Quick Links

→ Choose from 250+ Compressor Belts

→ Shop All Parts & Accessories

→ Request Repair & Troubleshooting or call 877-IAC-SERV

How to Tell If Your Air Compressor Belt Needs Replacing

Not sure if it’s time to replace the belt? These signs are clear indicators.

Visible Cracks, Fraying, or Glazing

Any cracking between ribs, frayed cords at the edges, or a shiny, glassy surface (“glazing”) means the belt has hardened and will slip under load. Replace, don’t re-tension a deteriorated belt.

Slipping or Squealing Noises

A chirp/squeal on start-up or during load/unload is classic belt slip. If tension and alignment are correct yet squeal persists, the belt is at end-of-life (or the sheave is worn). Replace the belt and inspect the sheave for groove wear.

Compressor Struggling to Build Pressure

If motor amps look normal but discharge pressure lags, or you’re seeing longer pump up times, suspect belt slip or stretch. After confirming there isn’t another mechanical issue, plan a belt change.

Burnt Rubber Smell or Black Dust in the Guard

Heat from slip leaves a hot rubber odor and fine black residue near the sheaves/inside the guard. That’s material loss, swap the belt and verify alignment/tension to prevent repeat slip.

Belt Looks Loose or Out of Alignment

A sagging span or a belt that rides high/low in the groove points to stretch or wrong belt profile. Sight the sheaves with a straightedge; if faces aren’t coplanar, correct alignment. If alignment is good but deflection is out of spec, replace the belt.

Rule of Thumb

If you see two or more of the above at once, plan a replacement now to protect bearings, sheaves, and uptime. Keep a spare on the shelf so a worn belt never becomes a line stoppage.

Tools & Parts You’ll Need

Before you start, gather the right tools and the correct replacement belt. Do this after LOTO, full depressurization, and when the unit is cool so you can work efficiently and safely.

Wrenches, Sockets, Screwdrivers

Sized for the belt guard fasteners and motor base/jacking bolts. A torque wrench helps hit OEM specs on reassembly. Keep a straightedge handy to verify sheave alignment when you reinstall.

Tension Gauge (Optional but Useful)

Great for setting belt tension to OEM spec and documenting the reading for your maintenance log. If you don’t use a gauge, follow the OEM’s deflection method for your belt span.

Correct OEM/Replacement Belt (Matched by Model/Size)

Match by compressor model and belt profile/length (e.g., A/B/C or 3V/5V/8V). For multi-belt drives, replace all belts as a matched set, don’t mix old and new. If model/part numbers are unclear, check the existing belt stamp and the unit nameplate.

IAC stocks 250+ belt options across 27 leading brands, making it easy to match the exact profile and length you need. Need help confirming the exact belt(s) you need? Call 877-IAC-SERV for expert help.

Safety Gear: Gloves & Eye Protection

Wear appropriate PPE; reinstall guards before restarting and verify no tools remain in the cabinet

→ Shop All Parts & Accessories

Safety First: Preparing for Belt Replacement

Working on a pressurized system requires proper shutdown and lockout. The steps below protect people and equipment but ensure to follow your facility’s EHS procedures and the OEM manual at all times.

- Power off & Disconnect

- Stop the compressor at the controller, then switch OFF at the local disconnect

- Apply LOTO: padlock the disconnect and tag it; keep the key with you

- Perform a try-start test at the controller to confirm zero electrical energy

- Only qualified personnel should work on electrical components

- Depressurize the Tank

- Open the manual drain or isolation valve to bleed the receiver to 0 psi; watch the gauge fall to zero

- Crack a downstream blow-off/bleed point briefly to verify there’s no trapped pressure in the line

- Confirm auto drains are not holding residual pressure

- Allow the System to Cool Down

- Wait until the motor, sheaves, belts, and coolers are cool to the touch

- Be mindful of hot surfaces and sharp edges inside the enclosure

- Remove the Belt Guard Safely

- Wear gloves and eye protection; Support guard panels so they don’t drop or flex

- Keep fasteners in a cup or bag so nothing is left inside the cabinet

- Visually confirm there’s no residual motion of the motor/compressor shafts before reaching in

Do not proceed if pressure cannot be verified at zero, if the disconnect can’t be locked and tagged, or if you are not trained for this work. In those cases, bring in a qualified technician. Call 877-IAC-SERV to schedule.

Step-by-Step: How to Replace an Air Compressor Belt

After completing LOTO, full depressurization, and cool-down, follow these steps to remove the old belt and install the new one correctly.

- Loosen The Drive to Remove the Old Belt

- Remove the belt guard

- Loosen the motor base/jacking bolts so the motor can slide toward the compressor

- Push the motor inward to relieve belt tension, then lift the belt off the sheaves

- Don’t pry the belt over a sheave with a screwdriver, this damages the belt and groove

- Inspect and Clean Before Installation

- Wipe dust from the guard and sheaves; clean grooves (no solvent that degrades rubber)

- Check sheaves for groove wear, nicks, or wobble; verify set screws/keys are secure

- If a multi-belt drive was installed, replace as a matched set, don’t mix old/new

- Verify Pulley (Sheave) Alignment

- Use a straightedge across the sheave faces (four-point contact) to confirm they’re coplanar

- Correct axial or angular misalignment before installing the new belt. Misalignment accelerates wear and causes squeal/heat

- Fit the New Belt

- Confirm the belt profile/length is correct. The belt should sit flush in the groove, not bottoming out and not riding too high

- Place the belt over the smaller sheave first, then the larger, rotating the sheaves by hand only to walk it into place

- Set Belt Tension

- Slide the motor away from the compressor to tension the belt; snug the jacking bolts

- Set tension to the OEM spec (preferred) or by deflection method using a tension gauge for your span

- Rotate by hand one full revolution to seat the belt, then re-check tension

- Re-Check Alignment and Secure Hardware

- Reconfirm straightedge alignment after tensioning (tension changes can pull alignment out)

- Tighten motor base/jacking bolts to spec. Verify all fasteners and guard mounts are accounted for

- Reinstall the Belt Guard

- Ensure no tools/rags are left inside. Close and secure the guard before restoring power

- Power Up and Test for Smooth Operation

- Remove LOTO, restore power, and bump start to observe tracking

- Run to load; listen for squeal, watch for vibration, and check for black dust

- Confirm normal amp draw, temperature, and pressure build

- After 15-30 minutes of operation, shut down and spot-check tension if you have a gauge

Pro Tips to Reduce Callbacks

- Re-Tension After Run-In: Belts relax as they sit. Recheck tension after 24-48 hours of normal operation and again at the next weekly check

- Log It: Record belt part number, tension reading/deflection method, alignment check, and run hours. Trend data helps predict the next replacement

- Recurring Slip? Reinspect alignment, sheave wear, and ventilation. If issues persist or escalate there may be underlying bearing, load, or control problems

Setting Proper Belt Tension (+ Why It Matters)

Improper belt tension is one of the quickest ways to shorten compressor life. The belt is the friction link between the motor and the pump/airend; if it slips, it makes heat and dust instead of airflow. If it’s over-tightened, it overloads the motor and airend bearings. Either way, you pay in energy, wear, and downtime.

Too loose → slip, noise, overheating

Expect start-up squeal/chirp, black rubber dust in the guard, glazing on the belt and sheaves, higher discharge temps, longer fill times, and wasted kWh.

Too tight → bearing wear, motor strain

Over-tension increases radial load on motor/airend bearings, elevates amperage and noise, and can crack mounts or sheaves over time.

Rule of Thumb

For many small to mid-span industrial drives, aim for about ½" deflection at mid-span with moderate thumb pressure. If the span is unusually long/short, adjust proportionally. Best practice: follow your OEM tension spec whenever available.

Use a Tension Gauge When Possible

A gauge removes guesswork and gives you a repeatable number to log. Quick method:

- Measure the belt span (center-to-center distance between sheaves)

- Seat the belt (rotate by hand one full turn)

- Apply the gauge force at mid-span and set tension to the OEM spec (or your site standard)

- Run test, then re-check and record the reading

Pro Tips from IAC Techs

- Re-Check After Run-In: New belts relax as they sit. Verify tension after 24-48 hours of operation.

- Multi-Belt Drives: Always install matched sets and tension evenly. If one belt is consistently looser, replace the set and inspect alignment/sheave wear.

- Avoid “Twist Tests.” Twisting to a certain angle is inconsistent, use a gauge or the deflection method.

- Persistent Slip After Correct Tension? Revisit alignment, sheave groove wear, ventilation/cooler cleanliness, and load profile.

Need help confirming belt profile or length?

→ Contact us or call 877-IAC-SERV

Ready to replace?

When to Call a Professional Instead

While belt replacement is straightforward, some situations call for expert help.

- If pulleys are damaged or misaligned

-

- Wobble, groove wear, alignment that shifts after tensioning

- If multiple belts or complex drive systems are involved

-

- Matched sets, multi-groove or variable-pitch sheaves, tight access

- If industrial unit downtime costs are high

-

- You need fast turnaround, verification readings, and documentation

- If safety concerns exist

-

- Can’t verify zero energy/pressure, abnormal heat/vibration, missing guards

IAC’s factory-trained techs can laser-check alignment, verify tension to spec, inspect/replace sheaves, and document results, keeping MTTR low and uptime high.

→ Request Repair & Troubleshooting

Preventing Future Belt Problems

Replacing the belt is only part of the solution, proper maintenance extends its life.

- Keep pulleys clean and aligned

- Inspect tension regularly (after run-in and on a set interval)

- Check for oil leaks that can damage belts

- Replace before catastrophic failure, not after

Keep a matched spare set on the shelf, log tension/alignment readings, and verify the guard is reinstalled after every service, small habits that prevent repeat slip, heat, and downtime. If you’d like belt inspection, tension checks, and documented replacements handled on a schedule, consider an IAC agreement.

Replace It Right, Keep Production Moving

Replacing a compressor belt doesn’t have to be complicated, as long as you have the right parts and follow the right process. Identify wear early (cracks, glazing, slip), prepare safely (LOTO, depressurize, cool-down), replace and align correctly, set/tune tension, and keep a simple PM rhythm to prevent repeat issues.

Recap: Spot the signs → prep safely → remove/install without prying → align sheaves → set proper tension (re-check after run-in) → log readings → keep pulleys clean and belts dry

Keep Your Lines Running with IAC

→ Shop Compressor Belts (250+ options across 27 leading brands)

→ Browse All Parts & Accessories

→ Request Repair & Troubleshooting or call 877-IAC-SERV